Ningbo Gongtie Smart Technology Co.,Ltd located in the east ocean of China, is a “national high-tech enterprise”, specialized in precise CNC lathe, gantry loader, and feeding system so on, below is a project introduction for hydraulic parts industry application.

Great productivity, robustness, quality of the materials and reliability are the distinctive features of GONGTIE machines.

宁波宫铁智能科技有限公司是一家专注于高精密车床、整机自动化、车削加工智能制造的研发和生产的国家高新技术企业。公司总部位于中国宁波市,欧洲研发中心位于意大利雷焦艾米莉亚。

下面是一个关于安全绳扣配件行业的客户案列介绍。

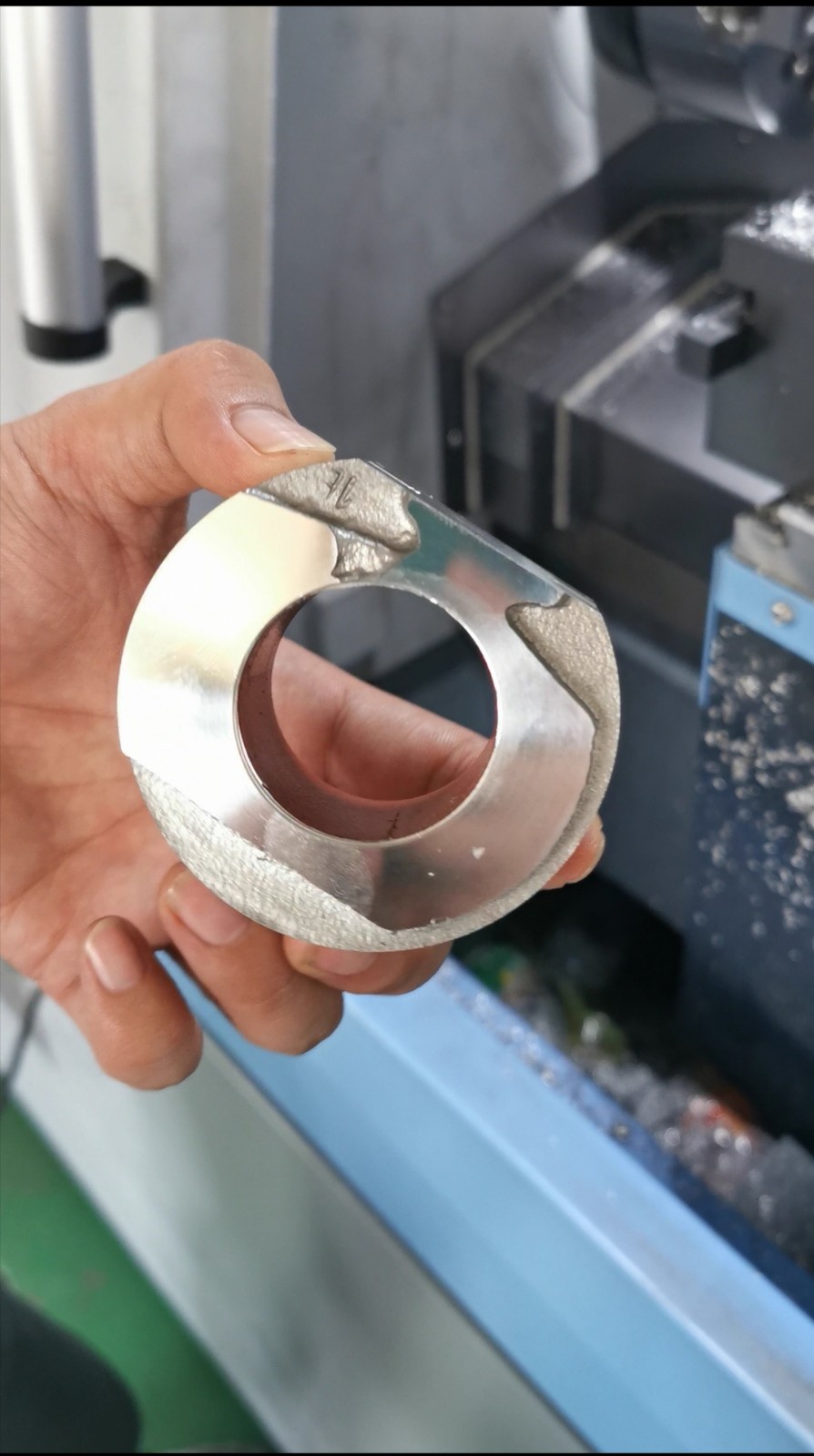

Customer’s parts:客户工件

Direct-Application: 直接应用

Below is some of the customer cases parts machined by our CNC LATHES for your reference.

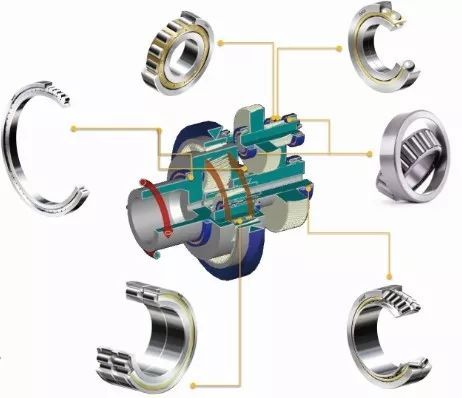

Indirect application: 间接应用

Typical customer: 典型客户

One precision machinery company for bearing buckle parts

Machining product: 实际加工的产品

Introduction: 机床选型介绍

As for this product, considering customer’s mass production requirement,

对于这个产品,考虑到客户的批量生产:

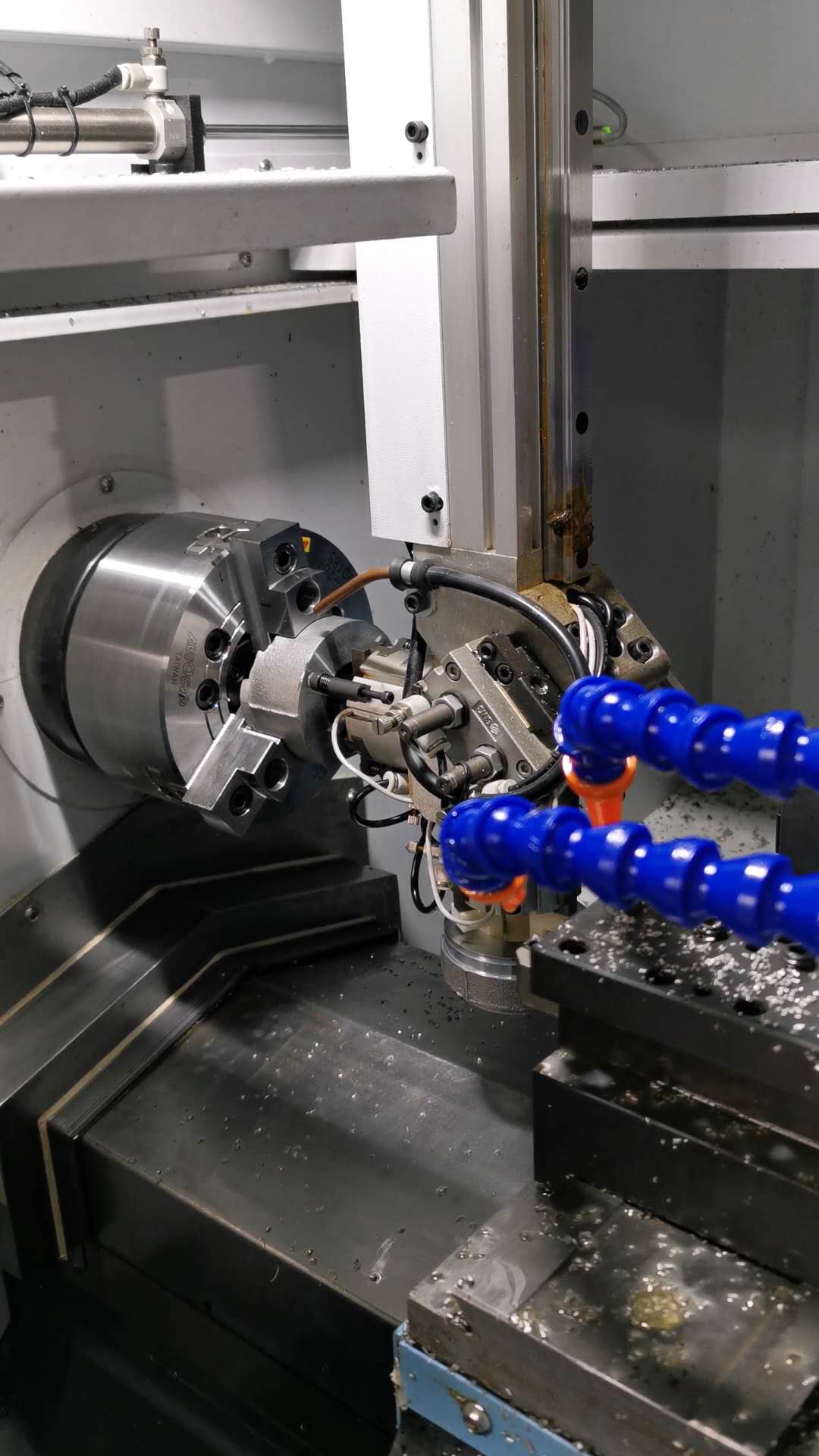

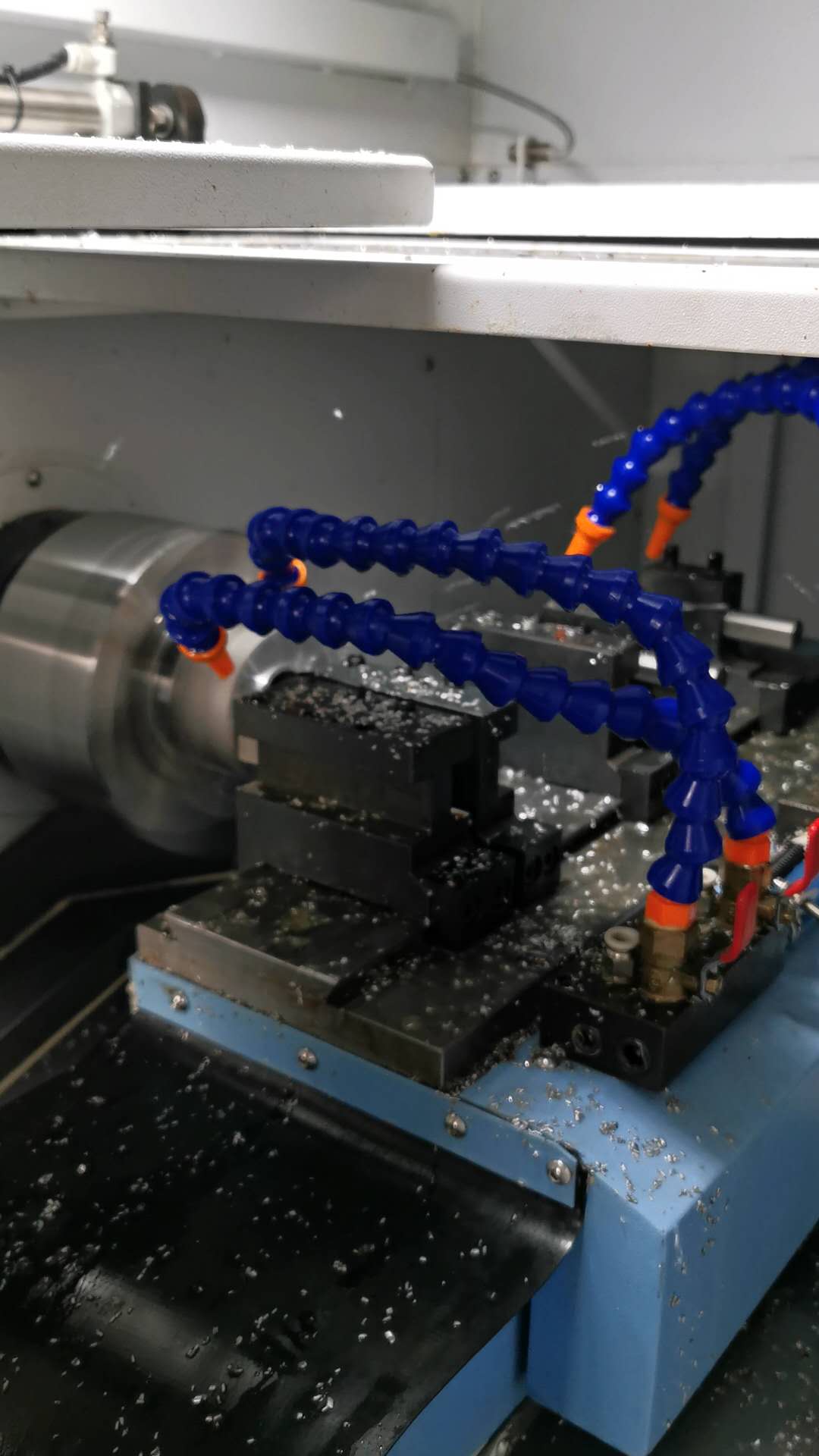

l We propose our precise CNC lathe with gantry loader, for saving the labor cost and improving the production efficiency.

我们推荐精密数控车床单机自动化,为了节约人工和提高生产效率

Specify solution: 具体的车型方案推荐

In order to have a continuous production,

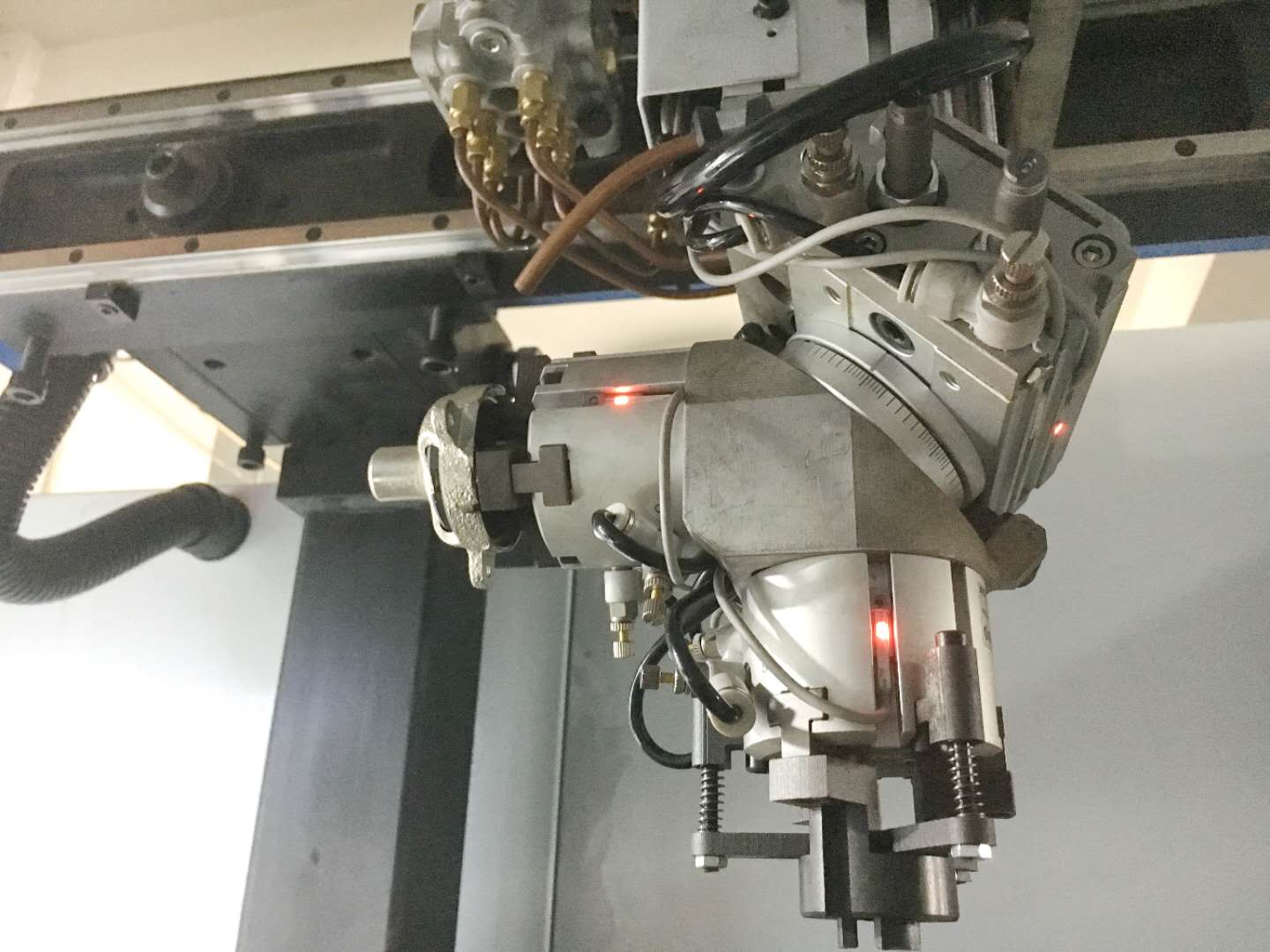

We use Q7 + Gantry loader in tray as the feeding system

The other added devices is as below: 其他增加的装置描述如下:

For the gantry loader, we use SMC pneumatic system for more reliable running.

同时,对于桁架自动送料机械手,我们采用SMC品牌的气动系统来提高稳定性。

The last even well take care for the packaging

最主要我们还完美定制包装

Type of tool selected for processing client's workpieces:

为加工客户工件所选的刀具类型:

加工产品 Processed Product(HW63Y) | |||

工序 (OP10) | 刀具 (T) | 参考刀杆 Tool arbor | 参考刀粒 Tool grain |

Rough end face, circle, chamfered |

T1 External tool | SCLCL 1616H-09 SCLCL1616H09 | CCGT 09T304AH CCGX09T304-LC(YD101) |

Finish end face, circle, chamfered |

T2 External tool | SCLCL 1616H-09 SCLCL1616H09 | CCMT 09T302NE CCGT09T304(PCD) |

Cut 1.5mm outer groove width |

| KGBASL 2020K22-15 B-JSTGL1616H16 | GBA43R 150-01(KPD001) TGP32R150 M30 |

Coarse interior bore, step chamfer |

T4 Hole boring cutter | S20R-SDUCR11-27A S20S-SDUCR11 | DCGT 11T304AH DCGX11T304-LC(YD101) |

Fine interior hole, step chamfer |

T5 Hole boring cutter | S20R-SDUCR11-27A S20S-SDUCR11 | DCMT 11T302 DCGT11T304(PCD) |

工序 (OP20) | 刀具 (T) | 参考刀杆 Tool arbor | 参考刀粒 Tool grain |

Rough end face, circle, chamfered |

T1 External tool | SCLCL 1616H-09 SDFCL1616H11 | CCGT 09T304AH DCGX11T304-LC(YD101) |

Finish end face, circle, chamfered |

T2 External tool | SCLCL 1616H-09 SDFCL1616H11 | CCMT 09T302NE DCGT11T304(PCD) |

Cut 7.0mm outer groove width |

T3 Slot cutter | KGDR 1616H-3T06 MGEHR1616-3 | GDGS3020N-020NB(KPD001) MGMN300-M CN2000 |

Coarse interior bore, step chamfer |

T4 Hole boring cutter | S20R-SDUCR11-27A S20S-SDUCR11 | DCGT 11T304AH DCGX11T304-LC(YD101) |

Fine interior hole, step chamfer |

T5镗孔刀 | S20R-SDUCR11-27A S20S-SDUCR11 | DCMT 11T302 DCGT11T304(PCD) |

Milling |

T6 milling tool | MEW 050R-15-4T-M 400R-50-22-4T | LOGT 150508FR-AM ARKT1604PDFR-MA-H01 |

参考刀杆型号与参考刀粒型号品牌均为日本京瓷(黑色字体) 绿色字体为本公司提供刀具的刀杆型号与刀粒型号,品牌多样,数量有限(以采购单为准) 3款产品共需7种刀具(底色表示刀具),OP10:蓝色2把,黄色2把,橙色2把,紫色1把!OP20:蓝色2把,黄色2把,绿色1把,橙色2把,红色1把,无底色一把(注:一把4个刀粒)共计蓝色4把,黄色4把,橙色4把,紫色1把,绿色1把,红色1把,无色一把(4刃) OP10刀架为16方右刀架2个,20方右刀架1个,20孔镗刀架2个,OP20刀架为16方右刀架2个,16方加长正刀架1个,20孔镗刀架2个,侧面动力头1个 加工工艺:节拍按实际要求可进行更改(可短可长),刀具数量也可减少(无固定)

Reference knife rod model and reference knife grain model are Japanese Kyocera (black font) Green font provides the company with the models of cutter rod and cutter grain, various brands and limited quantity (subject to the purchase order). The 3 products need 7 kinds of cutting tools in total (the background color represents the cutting tools), OP10: blue 2, yellow 2, orange 2, purple 1!OP20:2 blue, 2 yellow, 1 green, 2 orange, 1 red, one without base color (note: one with 4 knife grains) 4 blue, 4 yellow, 4 orange, 1 purple, 1 green, 1 red, one colorless (4 edges) OP10 tool holder has two 16-square right tool holder, one 20-square right tool holder, two 20-hole boring tool holder, OP20 tool holder has two 16-square right tool holder, one 16-square extended straight tool holder, two 20-hole boring tool holder, and one side power head Processing technology: the beat can be changed according to the actual requirements (short or long), the number of cutting tools can also be reduced (no fixed) | |||

Copyright © Ningbo Gongtie Smart Technology Co., Ltd. All Rights Reserved | Sitemap Powered by