Technique solution

Customer: *******

Supplier: Ningbo Gongtie Precision Machinery Co.,LTD

Data No.: ****

SOLUTION :

1. Products processing solution

1) customer: ****

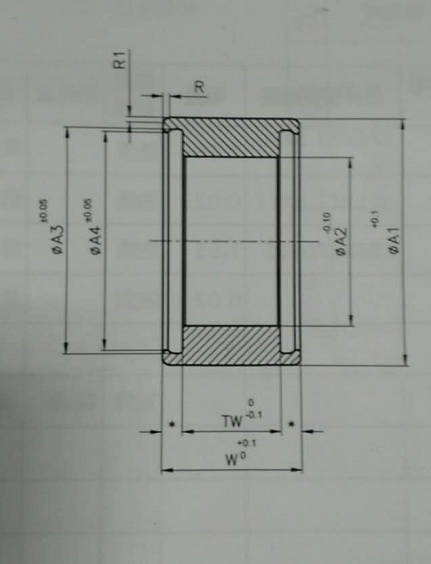

2) product:

3) Processing accuracy: Follow the drawing from customer

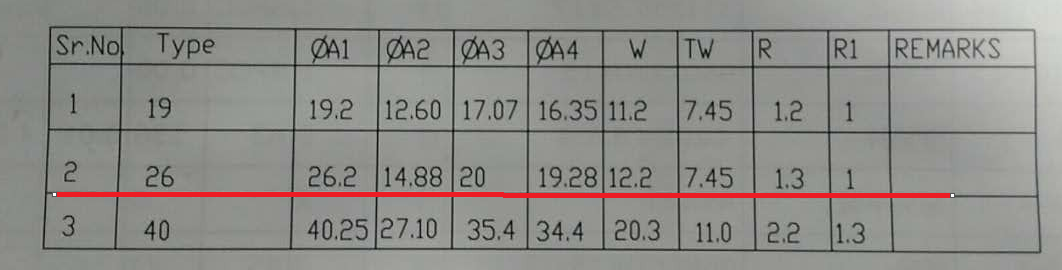

4) Work tool&fixture: precise spring collet chuck

5) The technique remarks:

5.1>the program will set up the tools life-time management (customer pre-set up the q’ty of the machining products, when reach it, automatically warning, for reducing the products scraps and the tools damage.)

6) GONGTIE company will do the best to provide the technique guidance for CNC lathes and related suggestion of the products processing technology.

7) Processing flow proposal:

the first CNC lathe process--- cycle time and process proposal(example of type 26) 1> flat head,OD(rough turning); 2> end face drilling hole; 3> ID(fine turning); 4>ID hole grooving-one ;5>ID hole grooving-two; 6> parts cutting | |||||||||||||

process | tools | Process speed(r/min) | Traverse (mm/r) | Cycle time(S) | |||||||||

flat head, OD(rough turning) | | S2500 | F0.11 | ≈6s | |||||||||

end face drilling hole | | S1300 | F0.07 | ≈9s | |||||||||

ID(fine turning) | | S2000 | F0.06 | ≈6.5s | |||||||||

ID hole grooving-one | | S1400 | F0.04 | ≈5s | |||||||||

ID hole grooving-two | | S1400 | F0.04 | ≈5s | |||||||||

Parts cutting | | S1600 | F0.04 | ≈6s | |||||||||

Processing time | ≈42 | ||||||||||||

Auto loading/unloading + air blowing | ≈4.5 | ||||||||||||

total | ≈46.5 | ||||||||||||

the second CNC lathe process--- cycle time and process proposal l(example of H=26): 1>flat head, chamfer angle; 2> ID chamfering | |||||||||||||

process | tools | Process speed(r/min) | Traverse (mm/r) | Cycle time(S) | |||||||||

Flat head, OD processing |

| S2500 | F0.1 | ≈3.5 | |||||||||

end face enlarging hole |

| S2000 | F0.09 | ≈4.5 | |||||||||

Processing time | ≈9.5 | ||||||||||||

Auto loading | ≈4.5 | ||||||||||||

total | ≈14 | ||||||||||||

8) Proposal equipment:

The first process: Precise linear guide-way CNC lathe with FLAT bed Q7+ bar feeder + finish parts receiver

The second process: Precise linear guide-way CNC lathe with flat bed Q7 with simple robot for loading&unloading

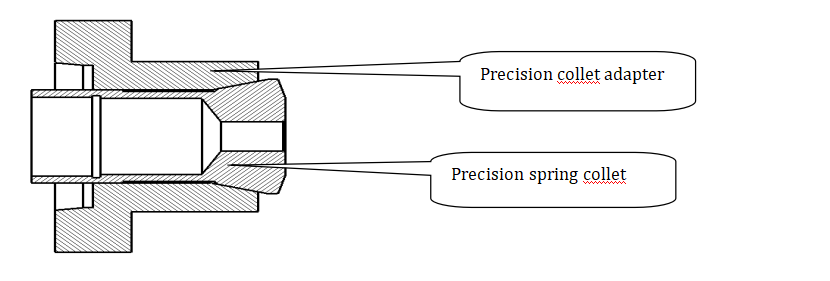

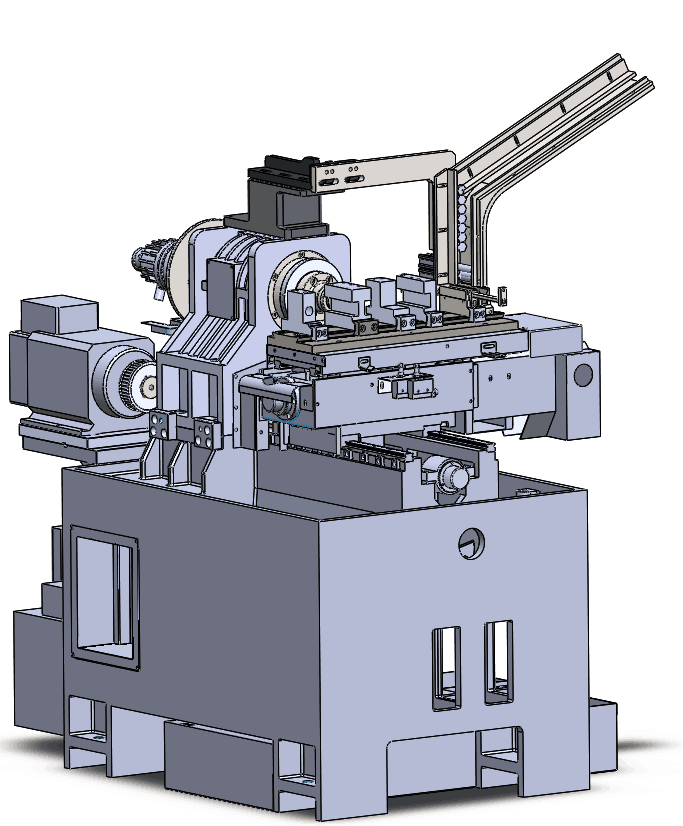

CNC lathe sketch:

8.1> Precise linear guide-way CNC lathe with flat bed

q 7

bar feeder

8.2> Precise linear guide-way CNC lathe with flat bed Q7 + bar feeder

v The second process: Precise linear guide-way CNC lathe with flat bed Q7 with simple robot for loading&unloading

The second process: Precise linear guide-way CNC lathe with flat bed Q7 with simple robot for loading&unloading

2. Parameters, configuration and price:

1) parameters:

Main parameters | UNIT | Q7 | ||

Capability | Max. swing diameter | mm | 400/98 | |

Max. turning length | mm | 300 | ||

Max. bar through-hole | mm | 26(35) | ||

Axis Stroke | X-axis travel | mm | 320 | |

Z-axis travel | mm | 315 | ||

Rapid Traverse | X/Z-axis | m/min | 20 | |

Spindle | Spindle nose size | N/A | A2-5 | |

Spindle hole through diameter | mm | 48 | ||

Spindle servo motor power | kW | (asynchronous )3.7/5.5 | ||

Spindle speed range | rpm | 0~5000 | ||

Work piece clamping method | N/A | homemade collet | ||

Toolholder | Number of tools | PCS | 5 | |

Toolholder type | N/A | Dovetail row of knives | ||

OPT | T-slot blade row+live tool | |||

Toolholder center height in radial | mm | 50 | ||

Tool size | mm | 16*16 | ||

Boring rod diameter | mm | 25 | ||

Accuracy | X\Z axis repeating postioning accuracy | mm | 0.002 | |

Others | Cooling motor capacity | L | 120 | |

hydraulic box capacity | L | 60 | ||

Required electric power | kVA | 8 | ||

Height from floor to spindle center | mm | ≈1070 | ||

Overall size(L*W*H) | mm | 1700*1300*1650 | ||

Net weight | kg | ≈1700 | ||

2) Configuration and price

NO. | ITEM | COMPONENT BRAND & SPEC. | ORIGINAL COUNTRY | QTY. | ||||

1 | Operation system | SYNTEC | TAIWAN | 1 | ||||

2 | Servo motor/drive | YASKAWA | JAPAN | 2 | ||||

3 | Spindle motor | CTB/SFC | CHINA | 1 | ||||

4 | Ball screw & linear guide-way | PMI/HIWIN | TAIWAN | 2,4 | ||||

5 | Spindle bearings | NTN P4 | JAPAN | 5 | ||||

6 | Spindle structure | Independent spindle with front three bearings and two after | BY GONGTIE | 1 | ||||

7 | Ball screw supporting method | Double supporting with pre-stretching structure | BY GONGTIE | 1 | ||||

8 | Hollow hydraulic rotary cylinder | 646/536 | TAIWAN COMPONENTS | 1 | ||||

9 | Hydraulic system | HUIZONG | TAIWAN COMPONENTS | 1 | ||||

10 | Electric cabinet with heat exchanger | NO. 5 | TAIWAN COMPONENTS | 1 | ||||

11 | Low voltage component | SCHNEIDER | FRENCH | 1 | ||||

13 | Tool-holder type | T-slot blade row | BY GONGTIE | 1 | ||||

14 | Bar feeder | PG326(¢3¢26) | TAIWAN | 1 | ||||

15 | Parts receiver | BY GONGTIE | 1 | |||||

Auto-loading/unloading system | ||||||||

No. | Kit | Brand&original country | QTY. | |||||

1 | Beam kit | GONGTIE | 1 set | |||||

2 | Beam linear guide-way | Taiwan PMI | 1set | |||||

3 | Parallel hand | JAPAN SMC | 1set | |||||

4 | Rotary cylinder | JAPAN SMC | 1set | |||||

5 | Air cylinder | JAPAN SMC | 1set | |||||

6 | Sensor/Magnetic switch | JAPAN SMC | 1set | |||||

7 | Gear wheel/rack(slant gear) | Taiwan | 1set | |||||

8 | Work-stocker system(in tray/pallet) | CHINA | 1set | |||||

9 | Loading/unloading device(mechanical claws) | GONGTIE | 1set | |||||

electrical system for gantry loader | ||||||||

1 | Servo motor | Inovance-china | 1set | |||||

2 | Servo system | Inovance-china(bus type CNC system) | 1set | |||||

3 | Controller system | Inovance-china | 1set | |||||

4 | Gear Reducer | Taiwan | 1set | |||||

5 | interface | Inovance-china | 1set | |||||

3. After-sales service

1) after finishing the machine, CUSTOMER party does the QC and try-run on site before the delivery.

2) In maintenance guarantee period (one year), we offer free maintenance components, and provide free technique help by phone, if the damage is not caused by human and beyond the period, we offer relevant services with paid components.

4. Attachments

Attached items | QTY |

Working instruction | 1 SET |

Machine guarantee card | 1 SET |

Electrics instruction | 1 SET |

Machine inspection report | 1 SET |

CNC system instruction | 1 SET |

Basic tools | 1 SET |

5. Lead time: 65 working days after signing contract

6. Delivery term: EXWORKS

7. Total price :

First process: Precise linear guide-way CNC lathe :Q7 + bar feeder (PG326) + receiving materials advice:

Lathe Price: **** RMB/SET

SEA Packing fee :***0RMB

Total: **** usd

v Second process: Precise linear guide-way CNC lathe with flat bed Q7 with simple robot:

Lathe +gantry loader price: ***RMB/SET

SEA PACKING FEE: ****RMB

Total: ****usd

8. Payment term: 30% prepay after signing contract, 70% after customer checking and before delivery.

9. Period of validity: 30days

Copyright © Ningbo Gongtie Smart Technology Co., Ltd. All Rights Reserved | Sitemap Powered by