Technique solution

Customer: *********

Supplier: Ningbo Gongtie Precision Machinery Co.,LTD

Data No.: ***********

Company Presentation:

Ningbo GongTie Precision Machinery Co.,LTD is a national high-tech enterprise, which integrates precise CNC lathes and industrial robots as a whole, specializes in precise CNC lathes, automatic integral-single CNC lathes, automatic production line. Bases on medium-small precise CNC lathes, sets up the machine automation as enterprise’ strategical core, targets to satisfy the market and the customer as the technique innovation’s motivation, scientifically and reasonably combines the precise CNC lathes with the machine unmanned together, sustainably improves the machine’s stability and practicability, becomes the domestic leading professional manufacturer and service supplier for precise CNC lathes and machines’ automation.

Established in 2006, with more than 100 employees, already got various of invention patents. GongTie is able to offer a complete engineering package from concept , design to manufacturing.

The company’s diversity machine series is widely used in automotive parts, valve, bearing, electric application , instrument, sanitary and more other industries, can realize various processing technology like drilling, turning, milling, boring, tapping, grooving and so on. We have set up sales office at several place and perfect sales representative network. And we completely follow the ISO9000:2000 quality management system and security management system on the development and manufacturing, to guarantee the quality and safety during the customer’s application. In addition, we have built up a perfect after-sales service system, can in-time make feasible reaction for the customer’s any inquiries or problems。

The CNC machine from GongTie has below advantages:

-- broaden application range

-- high precise, reliable features, fine finish and stable processing.

-- save labor costs

-- competitive price with high quality assurance

The company mission:

l Continuous innovation

l Quality priority

l Customer focused

l Solution driven

With our accurate, reliable products and perfect service system, we have won the trust of many users, and gradually built up a good brand impression in the CNC lathes automation industry.

SOLUTION :

1. Products processing solution

1) customer: *******

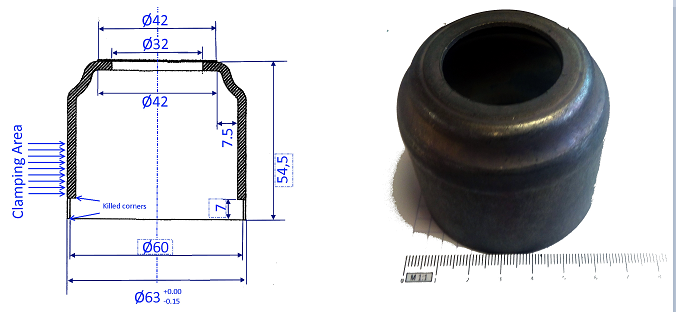

2) product:

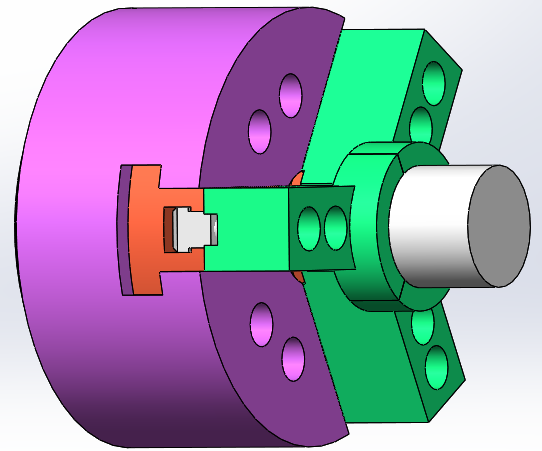

3) Work tool & fixture: 6 inch hydraulic chuck

******>the program will set up the tools life-time management (customer pre-set up the q’ty of the machining products, when reach it, automatically warning, for reducing the products scraps and the tools damage.)

5) GONGTIE company will do the best to provide the technique guidance for CNC lathes and related suggestion of the products processing technology.

6) Processing flow proposal:

cycle time and process proposal: 1>ID(rough turning); 2> ID(fine turning); | |||||||

process | tools | Process speed(r/min) | Traverse (mm/r) | Cycle time(S) | |||

ID(rough turning) | | S1500 | F0.09 | ≈3s | |||

ID(fine turning) | | S1800 | F0.08 | ≈5.5s | |||

Processing time | ≈10 | ||||||

Auto loading/unloading | ≈10 | ||||||

total | ≈20 | ||||||

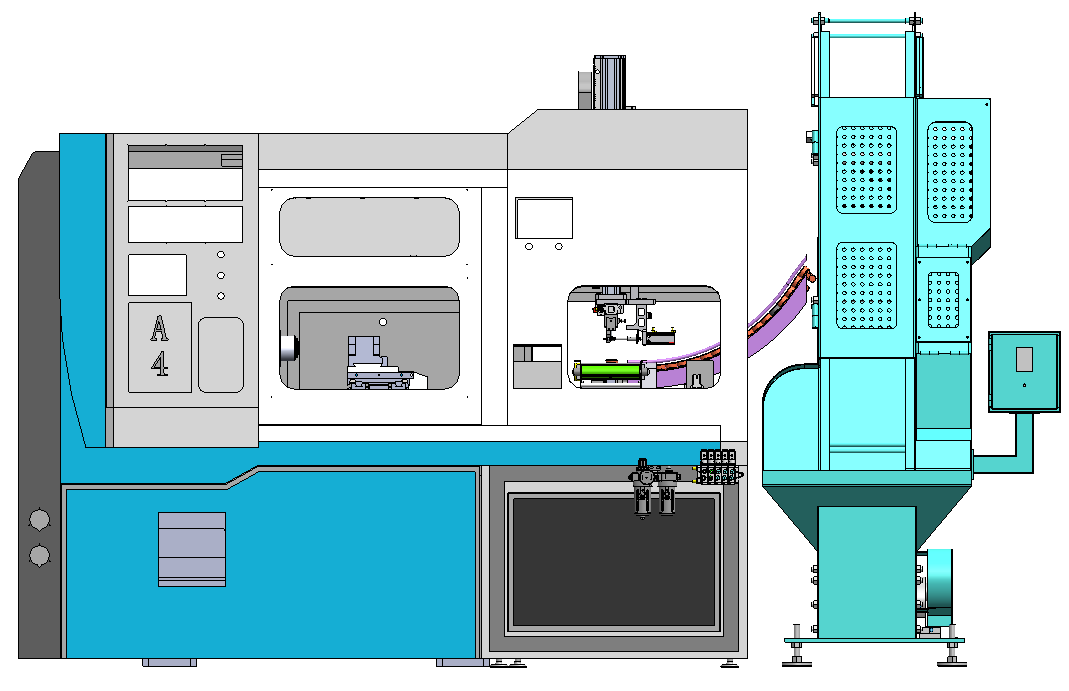

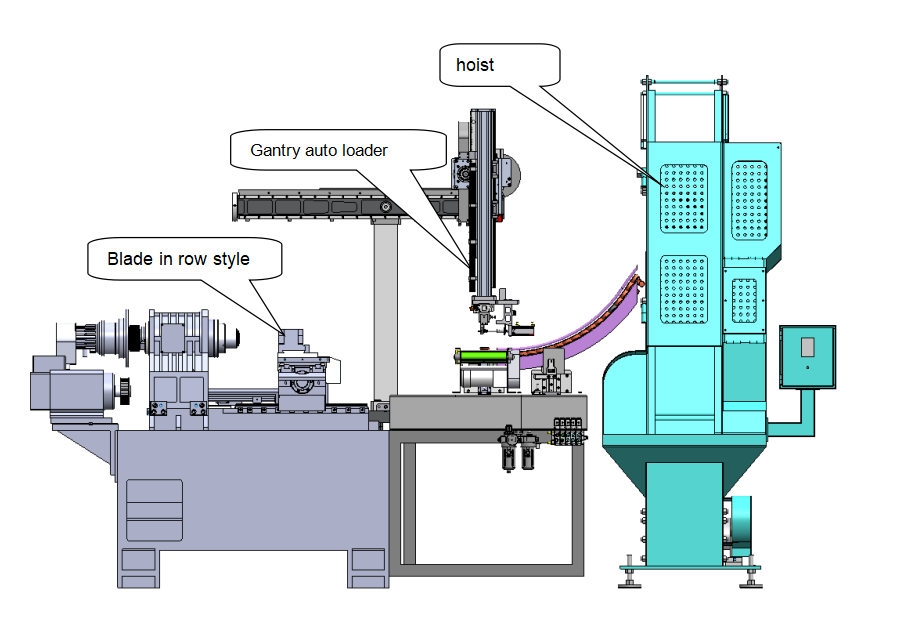

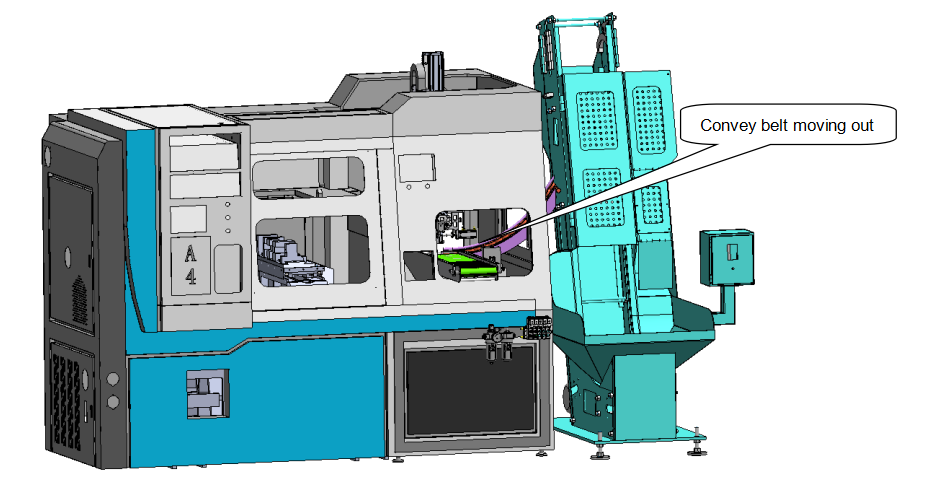

The second process: Precise linear guide-way CNC lathe with flat bed Q7 + gantry auto loader + hoist

8.1> CNC lathe outside total-view sketch:

Technique remarks: the raw parts is stocked by a hoist, first, to position the raw parts at the material staging exit, through the gantry auto loader feeding the raw part to the spindle work fixture, and during the machining time, the auto loader goes to grab new raw part, after finishing the machining, the auto loader take out (unloading) the finished part, meanwhile feed the raw parts to the spindle work fixture, then unloading the finished parts to the convey belt.

The advantages is the machining withe high precision, and more effective running, more stocking quantities, and realize the parts no scratch damages.

8.2> CNC lathe inside total-view sketch:

2. Parameters, configuration and price:

(1) PARAMETERS:

Main parameters | UNIT | Q7 | |

Capability | Max. swing diameter | mm | 400/98 |

Max. turning length | mm | 300 | |

Max. bar through-hole | mm | 26(35) | |

Axis Stroke | X-axis travel | mm | 320 |

Z-axis travel | mm | 315 | |

Rapid Traverse | X/Z-axis | m/min | 20 |

Spindle | Spindle nose size | N/A | A2-5 |

Spindle hole through diameter | mm | 48 | |

Spindle servo motor power | kW | (asynchronous )3.7/5.5 | |

Spindle speed range | rpm | 0~5000 | |

Work piece clamping method | N/A | homemade collet | |

Toolholder | Number of tools | PCS | 5 |

Toolholder type | N/A | Dovetail row of knives | |

OPT | T-slot blade row+live tool | ||

Toolholder center height in radial | mm | 50 | |

Tool size | mm | 16*16 | |

Boring rod diameter | mm | 25 | |

Accuracy | X\Z axis repeating postioning accuracy | mm | 0.002 |

Others | Cooling motor capacity | L | 120 |

hydraulic box capacity | L | 60 | |

Required electric power | kVA | 8 | |

Height from floor to spindle center | mm | ≈1070 | |

Overall size(L*W*H) | mm | 2450*1300*2450 | |

Net weight | kg | ≈2000 | |

2) Configuration and price

NO. | ITEM | COMPONENT BRAND & SPEC. | ORIGINAL COUNTRY | QTY. | ||||

1 | Operation system | SYNTEC | TAIWAN | 1 | ||||

2 | Servo motor/drive | YASKAWA | JAPAN | 2 | ||||

3 | Spindle motor | CTB/SFC | CHINA | 1 | ||||

4 | Ball screw & linear guide-way | PMI/HIWIN | TAIWAN | 2,4 | ||||

5 | Spindle bearings | NTN P4 | JAPAN | 5 | ||||

6 | Spindle structure | Independent spindle with front three bearings and two after | BY GONGTIE | 1 | ||||

7 | Ball screw supporting method | Double supporting with pre-stretching structure | BY GONGTIE | 1 | ||||

8 | Hollow hydraulic rotary cylinder | 646/536 | TAIWAN COMPONENTS | 1 | ||||

9 | Hydraulic system | HUIZONG | TAIWAN COMPONENTS | 1 | ||||

10 | Electric cabinet with heat exchanger | NO. 5 | TAIWAN COMPONENTS | 1 | ||||

11 | Low voltage component | SCHNEIDER | FRENCH | 1 | ||||

13 | Tool-holder type | T-slot blade row | BY GONGTIE | 1 | ||||

Auto-loading/unloading system | ||||||||

No. | Kit | Brand&original country | QTY. | |||||

1 | Beam kit | GONGTIE | 1 set | |||||

2 | Beam linear guide-way | Taiwan PMI | 1set | |||||

3 | Parallel hand | JAPAN SMC | 1set | |||||

4 | Rotary cylinder | JAPAN SMC | 1set | |||||

5 | Air cylinder | JAPAN SMC | 1set | |||||

6 | Sensor/Magnetic switch | JAPAN SMC | 1set | |||||

7 | Gear wheel/rack(slant gear) | Taiwan | 1set | |||||

8 | Work-stocker system(in tray/pallet) | CHINA | 1set | |||||

9 | Loading/unloading device(mechanical claws) | GONGTIE | 1set | |||||

electrical system for gantry loader | ||||||||

1 | Servo motor | Inovance-china | 1set | |||||

2 | Servo system | Inovance-china (bus type CNC system) | 1set | |||||

3 | Controller system | Inovance-china | 1set | |||||

4 | Gear Reducer | Taiwan | 1set | |||||

5 | interface | Inovance-china | 1set | |||||

3. After-sales service

1) after finishing the machine, CUSTOMER party does the QC and try-run on site before the delivery.

2) In maintenance guarantee period (one year), we offer free maintenance components, and provide free technique help by phone, if the damage is not caused by human and beyond the period, we offer relevant services with paid components.

4. Attachments

Attached items | QTY |

Working instruction | 1 SET |

Machine guarantee card | 1 SET |

Electrics instruction | 1 SET |

Machine inspection report | 1 SET |

CNC system instruction | 1 SET |

Basic tools | 1 SET |

5. Lead time: 65 working days after signing contract

6. Delivery term: EXWORKS

7. Total price :

Precise linear guide-way CNC lathe :Q7 + + gantry auto loader + hoist:

Lathe Price: ****RMB/SET

SEA Packing fee : ***RMB

Total: 190000RMB=**** usd

8. Payment term: 30% prepay after signing contract, 70% after customer checking and before delivery.

9. Period of validity: 30days

Copyright © Ningbo Gongtie Smart Technology Co., Ltd. All Rights Reserved | Sitemap Powered by